-

VZTF Automatic Self-cleaning Candle Filter

The plum blossom-shaped cartridge plays a supporting role, while the filter cloth wrapped around the cartridge functions as the filter element. When impurities accumulate on the outer surface of filter cloth (pressure or time reaches the set value), PLC sends a signal to stop feeding, discharge and back-blow or back-flush to detach the impurities. Special function: dry slag, no residual liquid. The filter has obtained 7 patents for its bottom filtration, slurry concentration, pulse back-flushing, filter cake washing, slurry discharge and special inner parts design.

Filtration rating: 1-1000 μm. Filtration area: 1-200 m2. Applies to: high solid content, viscous liquid, ultra-high precision, high temperature and other complex filtration occasions. -

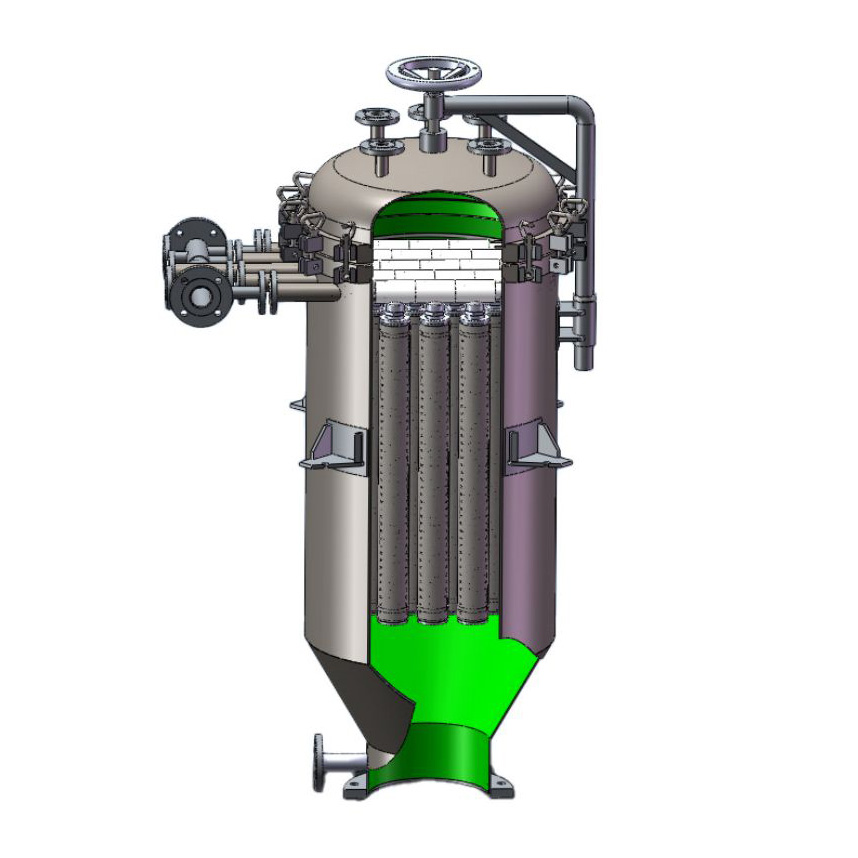

VGTF Vertical Pressure Leaf Filter

Filter element: stainless steel 316L multi-layer Dutch weave wire mesh leaf. Self-cleaning method: blowing and vibrating. When impurities build up on the external surface of the filter leaf and the pressure reaches the designated level, activate the hydraulic station to blow the filter cake. Once the filter cake is completely dried, start the vibrator to shake off the cake. The filter has obtained 2 patents for its anti-vibration cracking performance and the function of bottom filtration without residual liquid.

Filtration rating: 100-2000 mesh. Filtration area: 2-90 m2. Applies to: all operating conditions of plate and frame filter presses.

-

VB PP Liquid Filter Bag

VB Polypropylene filter bag is the filter element of VBTF Bag Filter, designed for the depth filtration of fine particles. Its highly permeable structure allows for the hold a large volume of impurities while maintaining a high flow rate. Additionally, it has excellent acid and alkali resistance, meeting FDA food-grade standards. The integrated plastic flange simplifies installation and disposal processes. The surface heat treatment ensures no fiber or leachable release, thereby preventing secondary contamination.

Micron rating: 0.5-200. Flow rate: 2-30 m3/h. Filtration area: 0.1-0.5 m2. Max operating temperature 90 ℃. Applies to: Food and beverage, petrochemical, coatings and paints, biomedicine, automobile manufacturing, etc.

-

VVTF Precision Microporous Cartridge Filter Replacement of Ultrafiltration Membranes

Filter element: UHMWPE/PA/PTFE powder sintered cartridge, or SS304/SS316L/Titanium powder sintered cartridge. Self-cleaning method: back-blowing/back-flushing. When impurities accumulate on the outer surface of filter cartridge (pressure or time reaches the set value), PLC sends a signal to stop feeding, discharge and back-blow or back-flush to remove the impurities. Cartridge can be reused and is a cost-effective alternative to ultrafiltration membranes.

Filtration rating: 0.1-100 μm. Filtration area: 5-100 m2. Especially suitable for: conditions with high solids content, a large amount of filter cake and a high requirement for filter cake dryness.

-

VAS-O Automatic Self-cleaning External Scraper Filter

Filter element: Stainless steel wedge mesh. Self-cleaning method: Stainless steel scraper plate. When impurities accumulate on the outer surface of filter mesh (differential pressure or time reaches the set value), PLC sends a signal to drive the scraper to rotate to scrape off impurities, while the filter keeps filtering. The filter has obtained 3 patents for its applicability to high impurity and high viscosity material, excellent sealing performance, and quick cover opening device.

Filtration rating: 25-5000 μm. Filtration area: 0.55 m2. Applies to: high impurity content and continuous uninterrupted production conditions.

-

VAS-I Automatic Self-cleaning Internal Scraper Filter

Filter element: Stainless steel wedge mesh/perforated mesh. Self-cleaning method: scraper plate/scraper blade/brush rotating. When impurities accumulate on the inner surface of filter mesh (differential pressure or time reaches the set value), PLC sends a signal to drive the scraper to rotate to scrape off impurities, while the filter keeps filtering. The filter has obtained 7 patents for its automatic shrinking and fitting function, excellent sealing performance, quick cover opening device, novel scraper type, stable structure of main shaft and its support, and special inlet and outlet design.

Filtration rating: 25-5000 μm. Filtration area: 0.22-1.88 m2. Applies to: high impurity content and continuous uninterrupted production conditions.

-

Stainless Steel 316L Powder Sintered Filter Cartridge

The cartridge is the filter element of VVTF Microporous Cartridge Filter and VCTF Cartridge Filter .

Made by high-temperature sintering of stainless steel powder, it has no medium falling off and no chemical pollutants. It has excellent high-temperature resistance and can withstand repeated high-temperature sterilization or continuous high-temperature use. It withstands up to 600℃, pressure changes and impacts. It has high fatigue strength and excellent chemical compatibility, corrosion resistance, and is suitable for acid, alkali, and organic solvent filtration. It can be cleaned and reused repeatedly.

Filtration rating: 0.22-100 μm. Applies to: Chemical, pharmaceutical, beverage, food, metallurgy, petroleum industry, etc.

-

VFLR High Flow PP Pleated Membrane Filter Cartridge

VFLR High Flow PP Pleated Cartridge is the filter element of VCTF-L High Flow Cartridge Filter. It is made from deep-layered, high-quality polypropylene membrane, offering excellent dirt holding capacity, long lifespan, and low operating costs. With a large effective filtration area, it guarantees low pressure drop and high flow rates. Its chemical properties are outstanding, making it suitable for various liquid filtration needs. Durable and sturdy cartridge frame due to integral injection molding technology.

Filtration rating: 0.5-100 μm. Length: 20”, 40”, 60”. Outer diameter: 160, 165, 170 mm. Applies to: Reverse osmosis system prefiltration, food & beverage, electronics, chemical industry, etc.

-

Titanium Powder Sintered Rod Filter Cartridge

The cartridge is the filter element of VVTF Microporous Cartridge Filter and VCTF Cartridge Filter. It is made from industrial pure titanium powder (purity ≥99.7%), which is sintered at high temperatures. It features a uniform structure, high porosity, low filtration resistance, excellent permeability, high filtration precision, resistance to acid and alkali corrosion, and high temperature resistance (280 ℃). It can be used for separation and purification of solid-liquid and solid-gas. No secondary pollution, easy operation, regenerable in-line, easy cleaning and reusable, and long service life (typically 5-10 years).

Filtration rating: 0.22-100 μm. Applies to: Pharmaceutical, food, chemical, biotechnology, and petrochemical industry.

-

VAS-A Automatic Self-cleaning Pneumatic Scraper Filter

Filter element: Stainless steel wedge mesh. Self-cleaning method: PTFE scraper ring. When impurities accumulate on the inner surface of filter mesh (differential pressure or time reaches the set value), PLC sends a signal to drive the cylinder at the top of the filter to push the scraper ring up and down to scrape off impurities, while the filter keeps filtering. The filter has obtained 2 patents for its applicability to lithium battery coating and automatic ring scraper filter system design.

Filtration rating: 25-5000 μm. Filtration area: 0.22-0.78 m2. Applies to: Paint, petrochemical, fine chemicals, bioengineering, food, pharmaceutical, water treatment, paper, steel, power plant, electronics, automotive, etc.

-

VC PP Meltblown Sediment Filter Cartridge

VC PP Meltblown Sediment Cartridge is the filter element of VCTF Cartridge Filter. It is made of FDA-certified polypropylene ultra-fine fibers with thermal-melt bonding process, without using any chemical adhesives. Combines surface, deep-layer, and coarse filtration. High precision with low pressure drop. Gradient pore size with outer loose and inner dense, resulting in strong dirt holding capacity. Effectively removes suspended solids, fine particles, rust, and other impurities in the liquid flow. Provides efficient filtration and long lifespan.

Filtration rating: 0.5-100 μm. Inside diameter: 28, 30, 32, 34, 59, 110 mm. Applies to: Water, food & beverage, chemical liquid, ink, etc.

-

VF PP/PES/PTFE Pleated Membrane Filter Cartridge

VF cartridge is the filter element of VCTF Cartridge Filter , which directly determines the filtration performance and the quality of the final product. It has high filtration efficiency, and large dirt-holding capacity. It not only meets USP Biosafety Level 6 standards, but also excels in meeting various special filtration requirements such as ultra-high precision, sterilization, high temperature, high pressure, etc., thus ideal for terminal filtration. Customization options are available to ensure it perfectly suits individual needs and specifications.

Filtration rating: 0.003-50 μm. Applies to: Water, beverage, beer and wine, petroleum, air, chemicals, pharmaceutical and biological products, etc.